Chillers Centrifugal Compressor Components

What is a Compressor Component?

Chillers Centrifugal Compressor Components

Chillers Centrifugal Compressor Components form an essential part of air or gas compression systems, specifically in centrifugal chillers. These chillers are widely used in various industrial, commercial, and HVAC (Heating, Ventilation, and Air Conditioning) applications. The Compressor Components in centrifugal chillers play a crucial role in ensuring efficient and reliable operation.

The primary function of Chillers Centrifugal Compressor Components is to compress refrigerant gasses, enabling the cooling process. These components are designed to handle large volumes of gas and operate at high speeds, delivering significant cooling capacity. They employ centrifugal force to compress the refrigerant and facilitate the heat exchange cycle, resulting in effective temperature control.

Importance of Chillers Centrifugal in Various Industries

Chillers Centrifugal play a vital role in numerous industries and applications. Here are some key reasons why they are highly valued:

HVAC Systems: Centrifugal chillers are extensively used in HVAC systems for commercial buildings, hospitals, shopping malls, and industrial facilities. They provide efficient cooling and temperature control, ensuring comfortable and controlled environments.

Industrial Processes: Many industrial processes require precise temperature control, and centrifugal chillers are ideal for these applications. They are employed in industries such as pharmaceuticals, food and beverage, chemical, and plastics, providing cooling for manufacturing processes, storage, and equipment cooling.

Data Centers: Data centers generate substantial heat due to the continuous operation of computer systems. Centrifugal chillers are used to cool the servers and maintain optimal temperatures, ensuring the reliability and longevity of critical IT infrastructure.

Power Generation: In power plants, centrifugal chillers are utilized for cooling various systems, including generators, turbines, and control rooms. They help maintain safe operating temperatures, ensuring efficient and uninterrupted power generation.

Process Cooling: Many industrial processes, such as metalworking, plastics manufacturing, and pharmaceutical production, require precise temperature control for optimal product quality and production efficiency. Centrifugal chillers play a crucial role in providing the necessary cooling for these processes.

Types of Chillers Centrifugal Compressor Components

Chillers Centrifugal Compressor Components are available in various types to suit different applications and performance requirements. Here are some common types of Chillers Centrifugal Compressor Components:

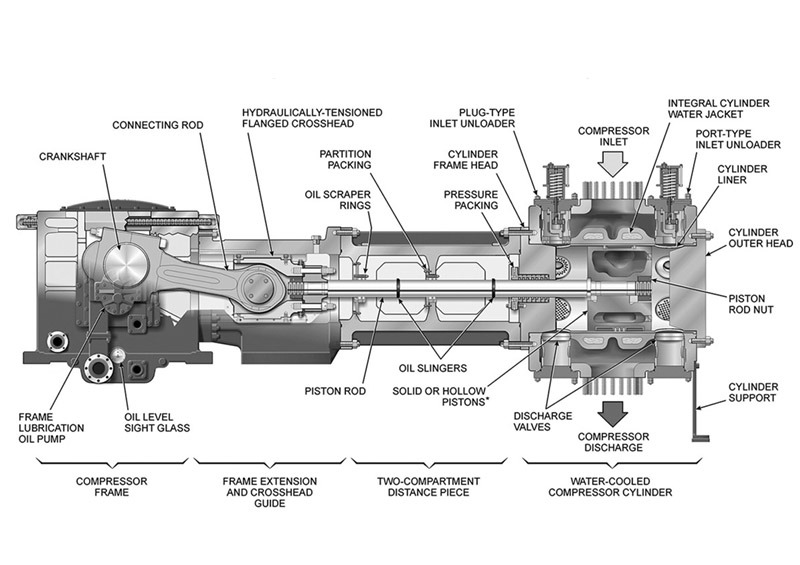

Impellers: Impellers are rotating components that use centrifugal force to compress the refrigerant gas. They consist of curved blades or vanes that accelerate the gas and direct it towards the diffuser.

Diffusers: Diffusers receive the high-velocity gas from the impeller and convert its kinetic energy into pressure energy. They slow down the gas flow and evenly distribute it to the next stage of compression.

Shafts and Bearings: The shafts and bearings provide support and enable the rotation of the impeller. They ensure smooth operation, reduce friction, and minimize wear and tear.

Housings: Housings or casings enclose the impeller and other internal components, creating a controlled environment for compression. They are designed to withstand high pressures and maintain the structural integrity of the compressor.

Types of Applications of Chillers Centrifugal in Compressor Components

Chillers Centrifugal Compressor Components find diverse applications across various industries. Some common applications include:

Air Conditioning: Chillers Centrifugal are extensively used in large-scale air conditioning systems for commercial buildings, such as offices, hotels, and shopping malls. They provide chilled water for cooling the air and maintaining comfortable indoor temperatures.

Industrial Cooling: Centrifugal chillers are employed in industrial cooling applications, such as cooling equipment, processes, and manufacturing facilities. They help regulate temperatures and ensure optimal operating conditions for machinery and products.

Refrigeration: Centrifugal chillers play a vital role in refrigeration systems, including cold storage facilities, food processing plants, and supermarkets. They provide the necessary cooling for preserving perishable goods and maintaining the quality and safety of refrigerated products.

Process Cooling: Many industrial processes require precise cooling to achieve desired product quality or facilitate specific reactions. Centrifugal chillers are used in industries such as pharmaceuticals, chemicals, and plastics to provide process cooling, ensuring efficient production and optimal results.

Chillers Centrifugal and Npro India

Chillers Centrifugal are indispensable components in various industries, providing efficient cooling and temperature control for HVAC systems, industrial processes, and critical applications. At Npro India, we take pride in being a leading manufacturer and stockist of high-quality Chillers Centrifugal and a wide range of Compressor Components.

With our expertise and commitment to excellence, we deliver reliable and innovative solutions that meet the diverse needs of our customers. Whether you require Chillers Centrifugal for HVAC installations, industrial processes, or specialized applications, we have the right products to cater to your requirements.

Choose Npro India for your Chillers Centrifugal needs and experience the performance, efficiency, and durability of our products. Contact us today to discuss your specific needs and discover how our offerings can enhance your cooling systems and applications.

Useful Links

Get Connected

Office No. 26, 2nd Floor

Phone No.

©2022. N Pro Enginnering India. All Rights Reserved.