Piston for Air Compressors in Compressor Components

What is a Compressor Component?

Piston for Air Compressors in Compressor Components

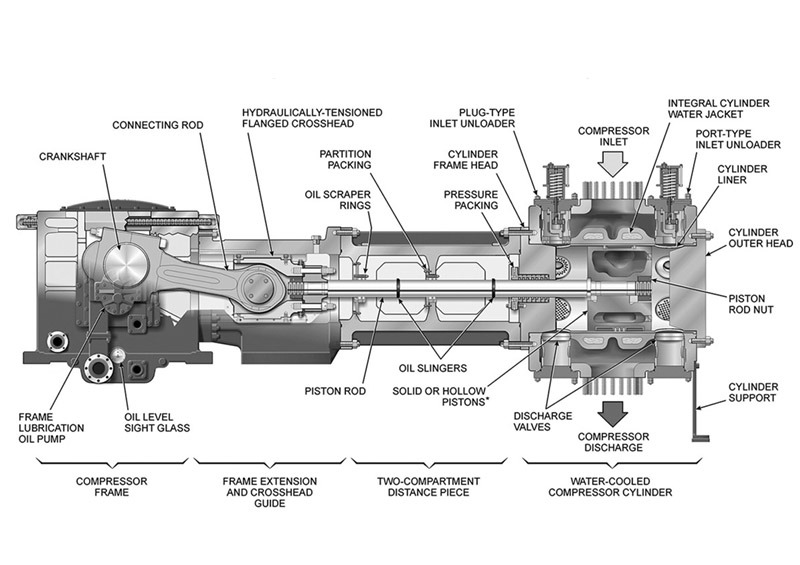

Among the essential components of an air compressor, the Piston holds a significant position. A component made of metal or alloy, known as the Piston, moves in a back and forth motion within the cylinder bore of the compressor. It forms a crucial part of the reciprocating compressor, which is widely used in various industrial applications.

The Piston’s primary function is to compress the air or gas within the cylinder bore. As the Piston moves downwards, it creates a vacuum that draws air into the cylinder. On its upward stroke, the Piston compresses the air or gas, increasing its pressure. This compressed air or gas is then discharged from the cylinder, ready for use in different applications.

Importance of Piston for Air Compressors in Various Industries

Piston for Air Compressors plays a vital role in numerous industries and applications. Here are some key reasons why Piston-driven air compressors are widely utilized:

Industrial Manufacturing: Piston-driven air compressors are extensively used in manufacturing processes that require high-pressure air, such as metalworking, automotive assembly, and packaging. They power pneumatic tools, control systems, and assist in the operation of heavy machinery.

Construction and Mining: The construction and mining sectors heavily rely on air compressors to power tools and equipment like jackhammers, drills, and pneumatic pumps. Piston-driven air compressors provide the necessary pressure for these applications.

HVAC and Refrigeration: Piston compressors are commonly employed in HVAC (Heating, Ventilation, and Air Conditioning) systems and refrigeration units. They help in maintaining and regulating temperature, ensuring optimal cooling and heating processes.

Oil and Gas Industry: In the oil and gas sector, Piston-driven air compressors are used for various operations, including gas transmission, pipeline maintenance, and well drilling. They provide the required power for pneumatic controls, instrumentation, and drilling equipment.

Medical and Dental: Piston-driven air compressors are utilized in medical and dental applications, such as dental drills, nebulizers, and oxygen concentrators. These compressors ensure a clean and reliable source of compressed air for critical healthcare procedures.

Types of Piston for Air Compressors in Compressor Components

Piston for Air Compressors are available in different types to suit various applications and requirements. Here are some common types of Piston for Air Compressors:

Single-Acting Piston: This type of piston has one face that interacts with the compressed air or gas. It provides compression during the upward stroke, while the downward stroke is powered by other means, such as gravity or a spring.

Double-Acting Piston: A double-acting piston has two faces, both of which contribute to the compression process. This design ensures efficient compression during both the upward and downward strokes, resulting in higher output and smoother operation.

Oil-Free Piston: Oil-free pistons are specifically designed for applications where air quality is crucial, such as in medical or food processing industries. These pistons eliminate the need for lubricating oil, ensuring clean and contaminant-free compressed air.

High-Pressure Piston: High-pressure pistons are engineered to handle extreme compression ratios and deliver compressed air or gas at significantly higher pressures. They are commonly employed in demanding industrial processes and specialized applications.

Types of Application of Piston for Air Compressors in Compressor Components

The versatility of Piston for Air Compressors allows them to be utilized in a wide range of applications. Some common uses include:

Powering Pneumatic Tools: Piston-driven air compressors are widely employed to power pneumatic tools like drills, impact wrenches, sanders, and paint sprayers. These tools benefit from the reliable and continuous supply of compressed air.

Industrial Automation: Compressed air is extensively used in industrial automation, driving pneumatic actuators, valves, and control systems. Piston compressors provide the necessary air pressure for the smooth operation of these automation components.

Material Handling: Piston-driven air compressors play a crucial role in material handling processes such as conveying, lifting, and sorting. They power pneumatic systems that control the movement and operation of various equipment in warehouses and production facilities.

Spraying and Coating: In industries like automotive manufacturing and painting, Piston-driven air compressors are used to power spray guns and coating systems. They deliver a consistent and controlled flow of compressed air, ensuring uniform and efficient application of paints and coatings.

Piston for Air Compressors and Npro India

Piston for Air Compressors is an integral part of Compressor Components, enabling efficient and reliable compression of air or gas. With their diverse range of applications across industries such as manufacturing, construction, healthcare, and more, these pistons are crucial for powering pneumatic systems and equipment.

At Npro India, we take immense pride in being a leading manufacturer and stockist of Piston for Air Compressors and a wide array of Compressor Components. We are committed to delivering high-quality products that meet the stringent requirements of our customers. With our expertise and dedication to excellence, we strive to provide solutions that optimize the performance and reliability of air compressors in various industries.

Choose Npro India for your Piston for Air Compressors needs and experience the reliability and efficiency of our products. Contact us today to discuss your requirements and explore how our offerings can enhance your compressed air systems.

Useful Links

Get Connected

Office No. 26, 2nd Floor

Phone No.

©2022. N Pro Enginnering India. All Rights Reserved.