Pump Components Sleeves

What is a Pump Component?

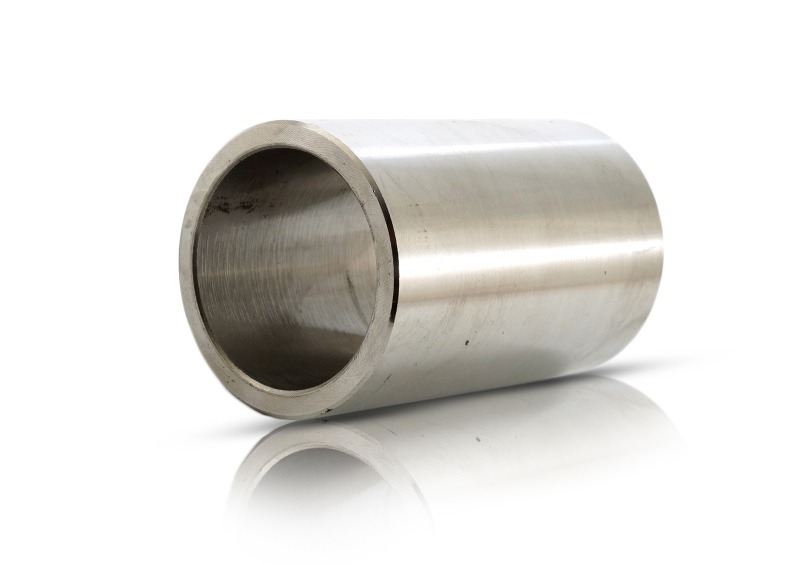

Explaining Sleeve in Pump Components.

A sleeve is a cylindrical-shaped component designed to fit precisely around the shaft of a pump. It acts as a protective barrier between the shaft and other pump components, providing numerous benefits. The sleeve is typically made from high-quality materials such as stainless steel or polymer composites, ensuring durability and resistance to wear and corrosion.

Importance of Sleeves in Various Industries.

Pump component sleeves hold immense importance in various industries due to their advantageous properties and functionality. Here are some key reasons why sleeves are crucial for optimal pump performance:

Shaft Protection: Sleeves provide a protective layer around the pump shaft, shielding it from abrasive particles, chemical corrosion, and wear caused by continuous operation. By reducing shaft damage, sleeves extend the overall lifespan of the pump, minimizing maintenance costs.

Alignment and Balance: Proper alignment and balance are critical for efficient pump operation. Sleeves assist in aligning the pump shaft with other rotating components, such as impellers and bearings, ensuring smooth and precise rotation. This alignment reduces vibration, noise, and unnecessary stress on the pump system, leading to improved longevity and reliability.

Lubrication Enhancement: Some pump sleeves are designed with built-in lubrication features, ensuring adequate lubrication between the shaft and sleeve. This reduces friction and heat generated during operation, thereby enhancing overall pump efficiency and reducing energy consumption.

Chemical Resistance: Different industries often handle corrosive or abrasive fluids. Pump sleeves manufactured from specialized materials provide excellent resistance to chemicals, acids, and abrasive substances, protecting the pump from internal damage and preventing contamination of the pumped fluid.

Types of Pump Component Sleeves.

When it comes to pump components sleeves, there are several types available, each designed to cater to specific needs and requirements. These sleeves offer varying features and benefits, ensuring optimal performance and durability in different applications. Here are some common types of pump component sleeves:

Standard Pump Sleeves:

Standard pump sleeves are the most common type and are widely used in various industries. They are typically made from durable materials such as stainless steel or polymer composites. These sleeves provide general protection to the pump shaft, ensuring smooth operation and minimizing wear and tear.

Chemical-Resistant Sleeves:

Chemical-resistant sleeves are specifically designed to withstand exposure to corrosive fluids and chemicals. They are manufactured from specialized materials that offer exceptional resistance to chemical corrosion. These sleeves ensure the integrity and longevity of the pump in applications where aggressive chemicals are involved, such as chemical processing plants and the oil and gas industry.

Abrasion-Resistant Sleeves:

Abrasion-resistant sleeves are ideal for applications where pumps handle abrasive fluids or encounter abrasive particles. These sleeves are constructed with materials that have high wear resistance, protecting the pump shaft from erosion and extending its lifespan. Industries such as mining, aggregate, and wastewater treatment often rely on these sleeves to maintain pump performance in harsh environments.

High-Temperature Sleeves:

High-temperature sleeves are designed to withstand elevated temperatures encountered in certain applications. They are manufactured using heat-resistant materials that can withstand extreme temperatures without compromising their structural integrity. These sleeves are commonly used in industries such as power generation, oil refining, and chemical processing, where high temperatures are prevalent.

Self-Lubricating Sleeves:

Self-lubricating sleeves feature built-in lubrication properties, eliminating the need for external lubricants. These sleeves are designed with materials that have inherent lubricity, reducing friction between the sleeve and pump shaft. By ensuring proper lubrication, they enhance the efficiency of the pump and minimize heat generation. Self-lubricating sleeves are particularly beneficial in applications where regular maintenance or lubrication is challenging.

Customized Sleeves:

In addition to the standard types mentioned above, pump component sleeves can also be customized to meet specific requirements. Customized sleeves are tailored to the unique needs of an application, considering factors such as size, material compatibility, and performance specifications. Npro Engineers India specializes in providing customized pump sleeves, offering a solution that precisely matches your pumping system requirements.

It’s important to select the appropriate type of sleeve based on the specific demands of your application. The team at Npro Engineers India can assist you in determining the most suitable sleeve type for your pump system, ensuring optimal performance, longevity, and cost-effectiveness.

Types of Applications of Pump Components Sleeves.

Pump component sleeves find applications across various industries and pump types. Here are some common examples:

Water and Wastewater Treatment: Pump sleeves ensure the longevity of pumps used in water and wastewater treatment plants, where corrosion and abrasion from chemicals and solid particles are prevalent.

Oil and Gas: In the oil and gas industry, where pumps handle highly corrosive fluids and endure harsh conditions, sleeves offer exceptional protection against corrosion and erosion.

Chemical Processing: Chemical pumps often encounter aggressive chemicals. Sleeves with excellent chemical resistance properties are crucial in maintaining pump integrity and performance.

Mining and Aggregate: Mining and aggregate operations involve the handling of abrasive materials and heavy-duty applications. Pump sleeves provide vital protection against wear and extend the operational life of pumps in these industries.

At Npro Engineers India, we take immense pride in being a trusted provider of high-quality pump components sleeves. Our commitment to superior manufacturing standards and stringent quality control ensures that our sleeves meet the highest industry standards.

Whether you need sleeves for water treatment, oil and gas, chemical processing, or any other industry, Npro Engineers India offers a wide range of sleeves tailored to your specific requirements. Our experienced team of professionals is dedicated to providing exceptional customer service and technical support, ensuring you receive the perfect solution for your pumping needs.

Partner with Npro Engineers India today and experience the reliability, durability, and performance enhancement that our pump components sleeves bring to your pumping systems.

Contact us now to explore our comprehensive range of sleeves and other pump components or to discuss your specific requirements.

Useful Links

Get Connected

Office No. 26, 2nd Floor

Phone No.

©2022. N Pro Enginnering India. All Rights Reserved.